CNC Tube Notcher

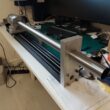

![]() I made some progress on my "desktop" CNC tube notcher. The hardware was beefed up and it's nearly ready for a test run on some soft 7005 aluminium tube.

I made some progress on my "desktop" CNC tube notcher. The hardware was beefed up and it's nearly ready for a test run on some soft 7005 aluminium tube.

![]() J'ai fais quelques progrès sur ma découpeuse de tube CNC de "bureau". Les composants ont été bodybuildés et c'est bientôt prêt pour un test sur de l'alu 7005 tendre.

J'ai fais quelques progrès sur ma découpeuse de tube CNC de "bureau". Les composants ont été bodybuildés et c'est bientôt prêt pour un test sur de l'alu 7005 tendre.

Poor Man / Cheap Guy’s CNC Tube Notcher

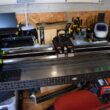

![]() For a while now I've been toying with the idea of doing some automated main tube mitering with a home made CNC. I started messing around with some Openbuilds components to do a plasma tube notcher, like those you find on YouTube. But ultimately I would want to drill and mill the cuts, like Co-Motion does (albeit with a proper heavy duty CNC lathe: see video at bottom of the post). The challenge is to do it with a cheaper/lighter solution that's tailored to thin wall bike tubing in alu, steel, stainless or titanium. It's still work in progress though...

For a while now I've been toying with the idea of doing some automated main tube mitering with a home made CNC. I started messing around with some Openbuilds components to do a plasma tube notcher, like those you find on YouTube. But ultimately I would want to drill and mill the cuts, like Co-Motion does (albeit with a proper heavy duty CNC lathe: see video at bottom of the post). The challenge is to do it with a cheaper/lighter solution that's tailored to thin wall bike tubing in alu, steel, stainless or titanium. It's still work in progress though...

![]() Depuis un certain temps, l'idée me trotte dans la tête de faire de la découpe automatisée des tubes principaux sur une CNC faite maison. J'ai joué un peu avec des elements Openbuilds pour faire un découpeur plasma, comme on en trouve des exemples sur YouTube. mais au final le but ça serait de faire une découpe a la fraise, comme le fait Co-Motion (avec un vrai tour CNC: voir vidéo en bas de billet). Le challenge c'est de le faire avec une solution moins cher et plus légère, adaptée a la découpe de tube de vélo fins en alu, acier, inox ou titane. C'est toujours a l'état du développement :-)

Depuis un certain temps, l'idée me trotte dans la tête de faire de la découpe automatisée des tubes principaux sur une CNC faite maison. J'ai joué un peu avec des elements Openbuilds pour faire un découpeur plasma, comme on en trouve des exemples sur YouTube. mais au final le but ça serait de faire une découpe a la fraise, comme le fait Co-Motion (avec un vrai tour CNC: voir vidéo en bas de billet). Le challenge c'est de le faire avec une solution moins cher et plus légère, adaptée a la découpe de tube de vélo fins en alu, acier, inox ou titane. C'est toujours a l'état du développement :-)

CNC Notcher: BikeCAD GCode Export

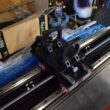

![]() Brent is releasing version 21 of BikeCAD with the GCode Miter Export function that we collaborated on while I was building the CNC Tube Notcher. This allows you to export GCode in just a few clicks directly from BikeCAD. The time it now takes to go from a BikeCAD drawing to the actual mitered tubes is significantly reduced. I find this particularly useful for down tubes that connect to tapered headtubes or that require a lot of water bottle holes. In a couple of minutes you get a fully mitered downtube with a perfect fit at both ends and the holes drilled in all the right places and inline.

Brent is releasing version 21 of BikeCAD with the GCode Miter Export function that we collaborated on while I was building the CNC Tube Notcher. This allows you to export GCode in just a few clicks directly from BikeCAD. The time it now takes to go from a BikeCAD drawing to the actual mitered tubes is significantly reduced. I find this particularly useful for down tubes that connect to tapered headtubes or that require a lot of water bottle holes. In a couple of minutes you get a fully mitered downtube with a perfect fit at both ends and the holes drilled in all the right places and inline.

Some curious minds out there have asked me for some more details on the actual machine so here is a list of the main components I used and a video of the latest setup:

- The X and Z axis is provided by the Gantry of a CNC router made by Rat Rig in Portugal (StrongHold Pro)

- The gantry is coupled with a lathe like bench made of Alu profiles sourced from Alu Profil in Austria

- The Y axis is a made of two rotary chucks sourced from Vevor

- The Spindle and the Variable Frequency Drive inverter is also from Vevor

- To control the 4 step motors I used OpenBuilds BlackBox Motion Control System X32

- To send the GCode to the controller I used OpenBuilds Control Software

- To hold the tube on one end and keep the step motor coupled to the tube after the 1st cut, I mofified a Pipe/Tube Expander with an extended arbor

- To hold the tube in place on the other end during the 2nd cut, I modified a Pipe Cutter (replaced the cutter with a bearing: see video/pic below)

The main benefit of this setup is that it uses a carbide bit instead of say a laser or plasma and it let's you cut alu, steel, stainless and titanium without heating/altering the tube. The main limitation is that you can only cut straight and round tubes.

PS: Other pictures and videos of the setup are available here: https://www.otmbikes.com/wpblog/?s=cnc